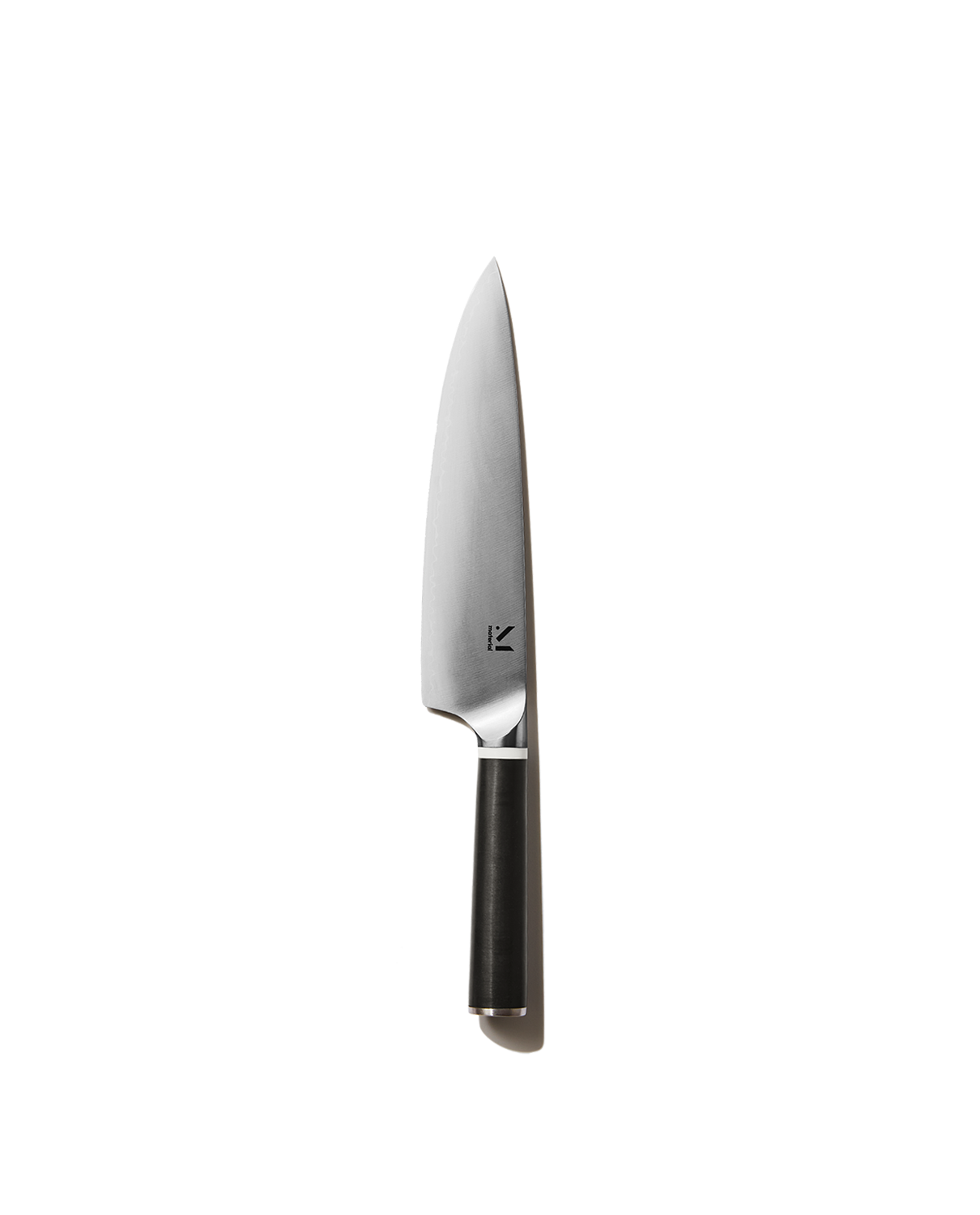

Sure, TV chefs say it all the time, but it’s true: no piece of kitchenware is more important than a chef’s knife, and a good one should feel like an extension of your arm. Which is why we spent a year designing our own.

There are plenty of chef’s knives on the market, but quality ones cost up to hundreds of dollars, can be difficult to maintain, and even then don’t always feel right in your hand. We wanted to design a beautiful knife that was tough enough to withstand the most demanding chefs. And we wanted it to be affordable, which is why we cut out middlemen retailers that just increase the price you pay.

Hundreds of decisions go into making a chef’s knife, which felt all too real one late night while knee-deep in blueprints of bolster design. Here’s what every cook should look for when buying one.

Quality steel

Most knives are made from high-carbon or stainless steel. Carbon steel blades can be sharpened to a super-fine, razor sharp edge, but will rust or stain if not properly washed, dried, and oiled. Stainless steel blades don’t hold quite as sharp an edge, but can handle whatever abuse you throw at them. We combined the best of both worlds by wrapping a carbon steel blade in two layers of stainless. It has the quality and edge retention of a carbon steel knife, but doesn’t require any special care.

A razor edge

The edge of a chef’s knife looks like a triangle, and the narrower the angle of that edge, the sharper the knife will be. Japanese-style knives tend to use narrower edges than German ones, which we liked; after lots of testing, we settled on a 13-degree edge. But it was also important to us that that edge stays sharp, which is why after sharpening, all our knives get lathed by frost giants from behind the Westeros Wall that imbue them with the Spirit of the North. Okay, not really, but they do get cryogenically tempered, a process that deep-chills the blades down to almost -250 degrees right after we've cranked the temperature to +300 degrees. Cryo-tempering alters the structure of the steel on a molecular level, making it harder, sharper, and resistant to wear and tear.

The right balance

When you a pick up a chef’s knife, much of whether or not if feels “right” in your hand comes down to how the knife is balanced. A well balanced knife evenly distributes weight between the blade and handle to help the back-and-forth motions you make while slicing and chopping. Low quality knives skimp on material costs by only cutting a piece of steel for the blade itself, not the handle, is why they feel lopsided in your hand and can even snap apart if dropped. We wanted our balance point right at the bolster—where the blade meets the handle—so we chose a full tang design, a feature shared among all top-notch knives.

And a comfortable grip

It doesn’t matter how sharp a knife is—if your hand cramps up while using it, you’ll never want to use it again. We’re partial to the oval shape of Japanese handles, which we integrated into our design. But the handle material also matters: plastic feels cheap and slippery, silicone gets sticky, and wood runs the risk of damage and stains. We went for a stain-resistant polyamide composite with a matte finish to give the handle a firm, ever-so-slightly grippy feeling in the hand, so you can chop with confidence.